Security threats: By using technology, it is very easy for hackers to get into the systems and cause havoc through theft and system unavailability.

This is where the problem lies, because the identification of these risks is only the first step. It is therefore important that supply chain risks be addressed by creating a framework that would assist in minimizing the effects of risks on the business and the supply chain.

The Role of Integrated Logistics in Risk Mitigation

Integrated logistics is a system that has all the supply chain members, and the information passes from one member to the other. It is useful in preventing any form of inconsistency in the warehousing, transportation, inventory, and order fulfillment.

Thus, it is possible to be ready for disruptions with the help of technology, Transport management system and real-time tracking offered by a proper logistics provider. These technologies provide the business with knowledge of the logistics networks and the events that are bound to happen in the network.

Technology-Driven Risk Management in Logistics

In the following manner, the implementation of advanced Transport management system and warehouse management system has impacted the management of risks in organizations.

It also improves the security of transactions since it provides an audit trail of all data in a way that cannot be modified. This makes it more effective in preventing fraud and is highly useful in industries such as the pharmaceutical and the food industry. Further it provides visibility to all stakeholders.

Ways to Reduce Risks through Warehousing and Inventory Control

The following are some of the effects of warehouse management: In situations where goods are perishable, high-valued, or JIT, then poor warehouse management results in severe supply chain consequences. It includes placement of the stock, use of technology in tracking the stock, and having a contingency plan in the event that the demand increases or when the stock runs out.

The following are the benefits that should be offered by a good WMS:

-

Stock Control: The right product should be put in the right place so that there is no scarcity of the products.

-

Automated Replenishment: A system of stock control that alerts the business when the stock is low.

-

Risk Buffering: This is a strategy that entails having a reserve stock in order to ensure that there is no interruption of supply.

The Importance of Multi-Modal Transportation in Risk Management

The disadvantage of using a single mode of transport is that it is dangerous to business since it opens up weaknesses. Some of the factors that may cause a delay in the shipment include a strike in a particular port, unfavorable weather for air shipment, or an increase in the price of fuel. Integrated logistics management is the combination of several transport modes in order to achieve the right transport flow from road, rail, sea, and air freight.

The firms that have adopted smart logistics planning and flexible routing are in a position to respond to any change and ensure that the products reach the intended destination in the shortest time possible.

Sustainability and Risk Reduction in Logistics

Sustainability is not only an environmental problem but also an organizational risk management problem. The benefits of green supply chain management to the companies include cost saving, legal requirements, and less vulnerability to oil prices.

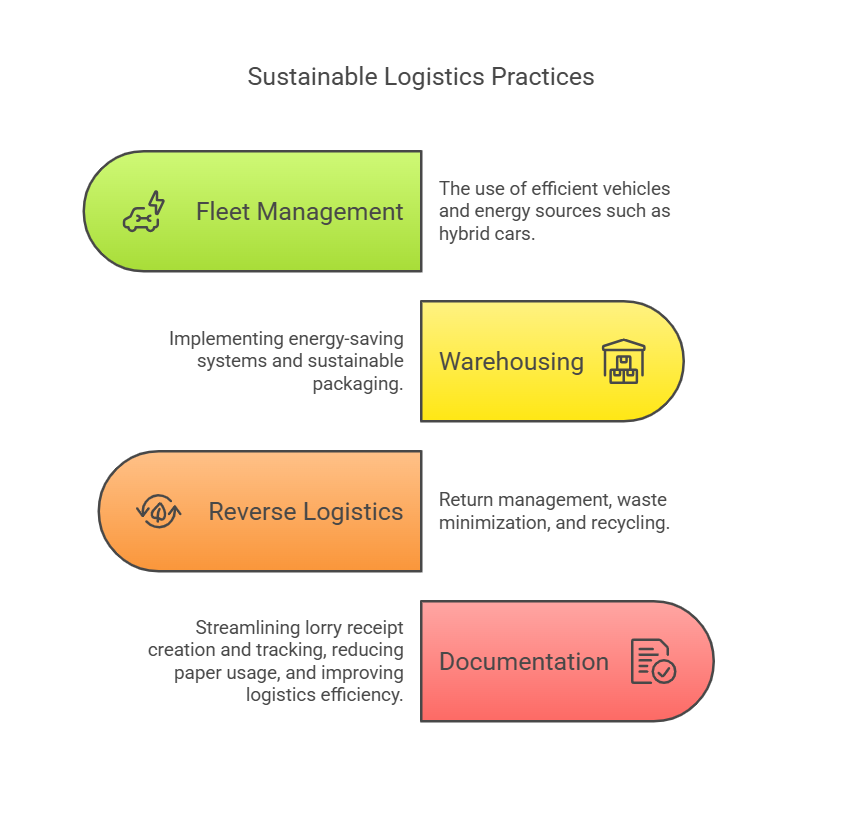

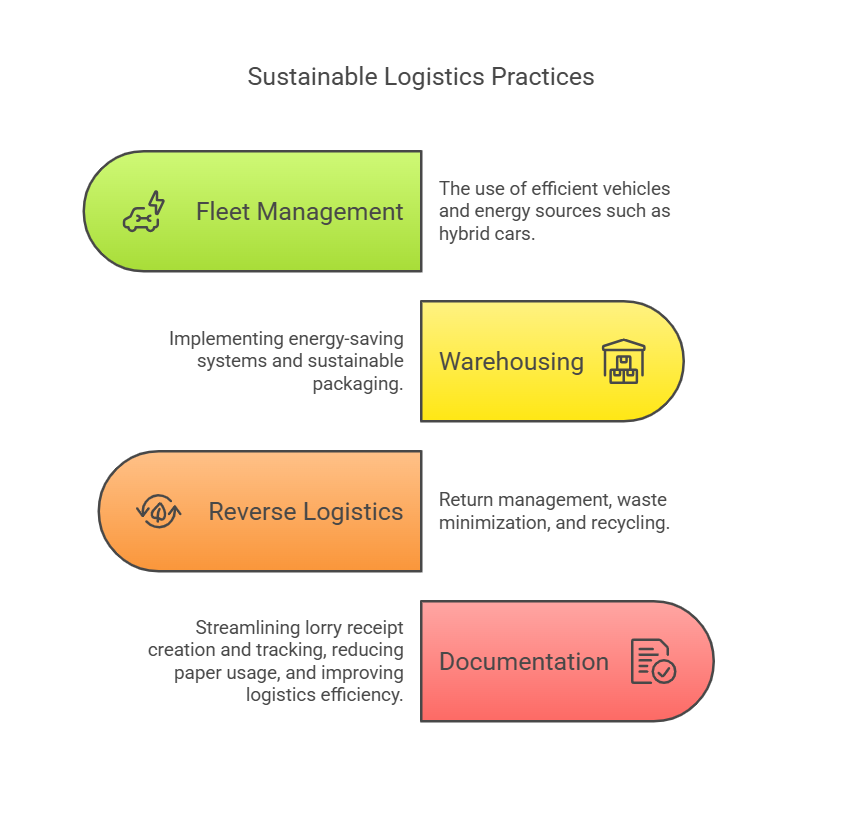

Sustainable logistics practices include:

-

Efficient Fleet Management: The use of efficient vehicles and energy sources such as hybrid cars.

-

Eco-Friendly Warehousing: Implementing

energy-saving systems and sustainable packaging.

-

Reverse Logistics: Return management, waste minimization, and recycling.

-

Digital Documentation Management: Streamlining lorry receipt creation and tracking, reducing paper usage, and improving logistics efficiency.

It also assists the businesses to minimize costs and uncertainties that are likely to be encountered due to changes in regulations or market sentiment.

How Crisis Management Strengthens Supply Chain Resilience

That is why there are always measures taken to reduce the likelihood of risks that are bound to occur. A crisis management plan is a business plan that helps an organization to handle any event that may occur in the business and impact it.

An ideal logistics partner provides:

-

Emergency Response: A team that is always alert for any risks that may happen and is able to handle them at any given time.

-

Contingency Supply Points: These are other supply points that are to be used in

case of failure in transport means.

-

Communication Transparency: Sharing of information with customers and stakeholders during disruptions.

Crisis management is an important aspect in any firm since firms that have developed ways of handling crises are well placed to recover quickly, maintain their customers' confidence, and reduce their losses.

Why Partnering with the Right Logistics Provider Matters

Another area that should be well managed by a competent logistics partner is supply chain risk management. A reliable supplier is one who ensures that the supply chain is safeguarded and can be made to suit the company and be effective.

For the companies who wish to have risk management in addition to the integrated logistics solution, Kusshal Loggistics offers third-party logistics, warehousing, and visibility services. For information on how Kusshal Loggistics can safeguard your business, please visit Kusshal Loggistics.